Why IC360

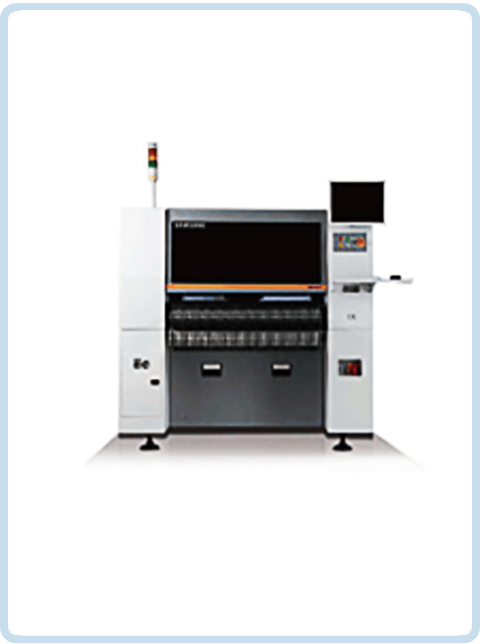

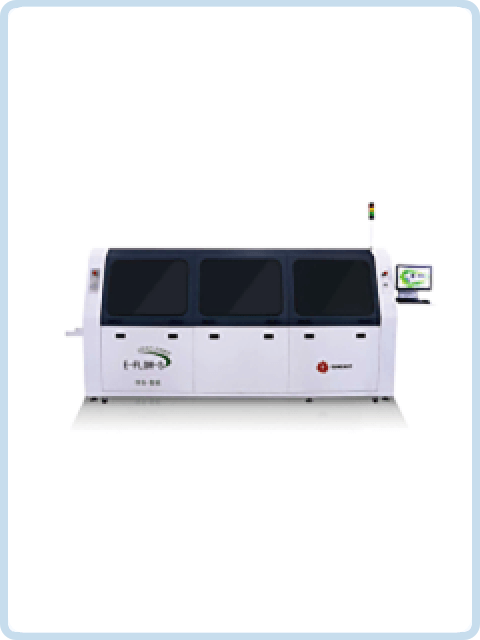

IC360 is committed to providing customers with professional,

high-quality and fast PCB assembly turnkey solution. From WLCSP &

flip-chip to the smallest passive and oddly-shaped components, high

density assembly, low voiding soldering, proper underfll, edge bonding

- including PCB protection with nano coating and conformal coating -

and understanding materials impact on signal integrity, we can help

you apply the latest technologies and techniques for flawless assembly

and maximum performance.

Turnkey

PCB Manufacturing, components sourcing and in-house assembly,

whole project management available at IC360

Quick-turn Prototyping

Support from 1 to 300 pcs quantities, enable you to go from design

to function prototype faster and with confidence

On-Demand Fabrication

Agile fabrication process meets demand, Experienced Team offers

fantastic experience

Strong Supply Chain Management

Deep cooperation with 3000+ original electronic components

manufacturers and their authorized agents and distributors

Smart BOM System

Intelligently recognizing ,analyzing, matching, comparing and

recommending for your non-template BOM list by uploading without

registration

Overall Cost Reduction

Eliminate intermediate brokers,Reduce costs by 15%-45%, Improve

purchase and production efficiency